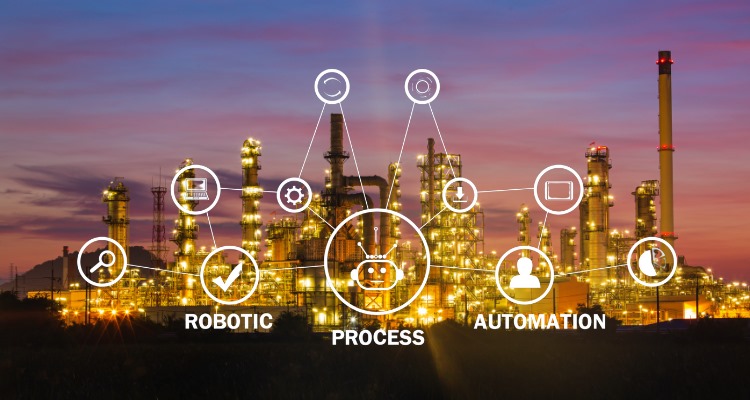

Digitizing the Oil & Gas Sector: Process Automation for Safer and Cost-Effective Operations

The oil and gas industry faces increasing pressure to enhance safety, reduce operational costs, and ensure regulatory compliance — all while dealing with volatile markets and complex supply chains. In this landscape, digital transformation through industrial automation is not just an option — it’s a strategic imperative.

At Softcon, we help upstream, midstream, and downstream companies embrace automation to optimize operations, improve safety, and gain real-time control over assets — from oil fields to refineries.

The Challenges in Traditional Oil & Gas Operations

- Manual inspections and data entry prone to human error

- Limited visibility across remote or hazardous sites

- Inefficient energy usage and unplanned equipment failures

- High OPEX due to reactive maintenance and downtime

- Complex compliance requirements (like OISD, API, ISO 50001)

Automation solves these challenges by connecting machines, sensors, and systems to monitor and manage operations more effectively.

Benefits of Industrial Automation in Oil & Gas

1. Enhanced Operational Safety

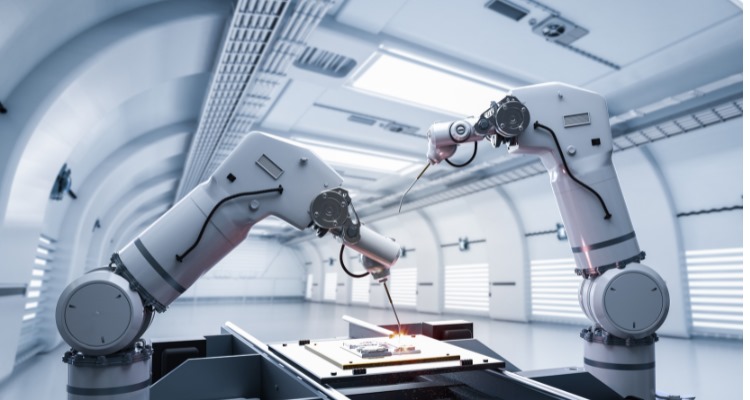

Automation minimizes human intervention in hazardous zones, using sensors, SCADA, and emergency shutdown systems.

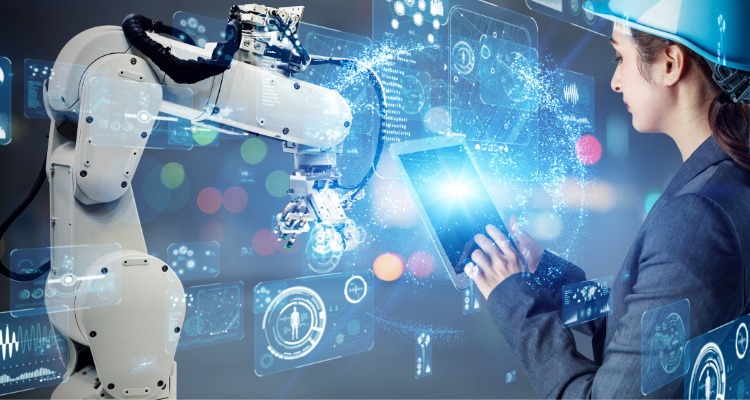

2. Real-Time Process Monitoring

With integrated PLC, DCS, and SCADA, operators can monitor pressure, temperature, and flow across pipelines and plants in real-time.

3. Predictive Maintenance and Asset Health

By analyzing sensor data, companies can detect potential equipment failures early, reducing unplanned downtime and extending asset life.

4. Energy Optimization and Cost Control

Advanced control systems improve combustion efficiency, optimize pump operations, and reduce energy waste.

5. Regulatory Compliance and Reporting

Automated logging of operational data ensures compliance with national and international standards and simplifies audits.

Softcon’s Automation Capabilities for Oil & Gas

We offer tailored end-to-end automation solutions across the oil & gas value chain:

- SCADA & DCS Systems for plant-wide control

- PLC-based control panels for drilling and extraction units

- Real-time alarm systems and emergency shutdown (ESD) systems

- IoT & sensor integration for pipeline integrity monitoring

- Tank farm automation and flow control

- Centralized control rooms and data dashboards

Case Study: Refinery Process Optimization in Pune

A midstream oil company in Pune engaged Softcon to automate their blending and distillation units. We deployed:

- SCADA-based real-time control

- IoT-driven flow measurement

- Predictive failure alerts

Results:

25% reduction in manual errors

30% less energy consumption

100% compliance with OISD standards

Increased throughput with minimal downtime

Key Technologies We Use

- Supervisory Control and Data Acquisition (SCADA)

- Programmable Logic Controllers (PLC)

- Distributed Control Systems (DCS)

- Remote Terminal Units (RTUs)

- Industrial IoT & Smart Sensors

- Manufacturing Execution Systems (MES)

Conclusion: Future-Proofing Oil & Gas Operations with Automation

The oil and gas sector must evolve to remain competitive and safe in today’s digital economy. With the right automation strategy, companies can not only reduce costs and improve reliability — but also build smarter, more resilient infrastructure.

Softcon delivers automation solutions that empower oil & gas companies in India and beyond to take control of their operations with real-time visibility, safety-first designs, and scalable digital tools.

Get in Touch with Softcon

Website: www.softcon.net.in

Phone: +91 8888825314 | +91 8888825315

Email: info@softcon.net.in